At Craftz, everything starts from craftsmanship CRAFTSMANSHIP

Craftz supplies packaging to a wide range of manufacturers making products closely related to

people’s daily lives: mainly companies in the food sector,

but also including

manufacturers of sanitary products and pet-related products.

To realize the kind of packaging that manufacturers want and that consumers want, we undertake packaging

manufacturing based on craftsmanship.

Meeting customers’ needs

with

Craftz’s craftsmanship

Beyond Package

Three reasons Why choose Craftz

-

01

QUALITY FIRST

- Quality management that emphasizes safety and peace of mind

- Realizing stable supply

- An integrated production system

-

02

TECHNICAL ABILITY

- Capability to reproduce designs precisely using a robust coordination system

- A spirit of inquiry that is constantly striving for technical improvement

- Curiosity and a proactive attitude toward adopting new equipment

-

03

PROMPT RESPONSE

- Responsive sales with technical capabilities and knowhow

- Responsive testing and problem-solving using in-house research facilities

- Responsive global delivery

01

QUALITY FIRST

Quality management that emphasizes safety and peace of mind

We implement quality management that emphasizes safety and peace of mind, with a constant customer focus, to ensure that we maintain thorough compliance with ISO quality standards and deliver only products that meet rigorous quality standards.

Realizing stable supply

We ensure stable supply to customers through the establishment of an extensive network linking us with raw materials products and product manufacturers throughout the world, enabling a flexible response to change of all kinds.

An integrated production system

We can supply products with stable quality, thanks to integrated, in-house management of every stage from order receipt through to delivery, and thanks to the consistent maintenance of high quality standards through an integrated production system.

02

TECHNICAL ABILITY

Capability to reproduce designs precisely using a robust coordination system

We have put in place a coordination system that links the sales function with plate-making and with the factory, and we are able to reduce the amount of time that customers need to spend taking part in meetings thanks to intensive advance preparation. We can accurately reproduce the designs that customers want.

A spirit of inquiry that is constantly striving for technical improvement

We proactively undertake investigations and research on the latest materials at the research laboratories located in our head office, enabling us to accumulate knowhow and data.

Curiosity and a proactive attitude toward adopting new equipment

We are constantly collecting up-to-date information about manufacturing equipment, and we proactively invest in necessary equipment, enabling us to respond effectively to customer needs.

03

PROMPT RESPONSE

Responsive sales with technical capabilities and knowhow

Our sales team possesses a wealth of knowhow, and can respond quickly to customer requests, offering the best possible solutions.

Responsive testing and problem-solving using in-house research facilities

As we have our own research laboratories in our head office, we can proactively undertake investigations and research on new materials that meet changing needs, and we can use the knowhow and data that we have accumulated to offer up-to-date proposals that meet customers’ requirements.

Responsive global delivery

We have put in place a delivery system in line with customers’ expectations, and we are able to realize flexible shipment not only within Japan but also overseas.

Overview of Craftz’s

proposal-based sales

and research facilities

Craftz’s distinctive sales model – Proposal-based sales

Our sales team implements coordinated sales that covers every stage from

plan

formulation through to proposal submission

Craftz’s sales team has direct exposure to the voice of frontline staff, independently

collecting the tools—including materials,

techniques and market related data—that it needs to meet

customers’ requirements.

Being able to communicate closely with the customer helps us to win customers’ trust, so that they are

willing to entrust projects to us.

A sales team that possesses high levels of technical expertise and knowhow

Craftz’s sales team, which has a wealth of expertise and specialist knowhow, is given a

high degree of discretionary authority,

enabling them to respond promptly to queries.

With the research facilities located in the company’s head office being able to implement testing at an

early stage,

and because it is the sales staff who liaise with the paper manufacturers,

customers can

just deal directly with Craftz’s sales staff, without needing to talk to a lot of other people.

Craftz’s Head Office in Tokyo has research laboratory equipped with the latest

equipment.

These research laboratories are closely integrated with the company’s sales team, and enable analysis

and development work to be undertaken in the head office. The head office can undertake analysis of

potential issues that might affect packaging, including content analysis using MOCON and a comprehensive

range of other measuring devices and image processing using 3D microscopes.

-

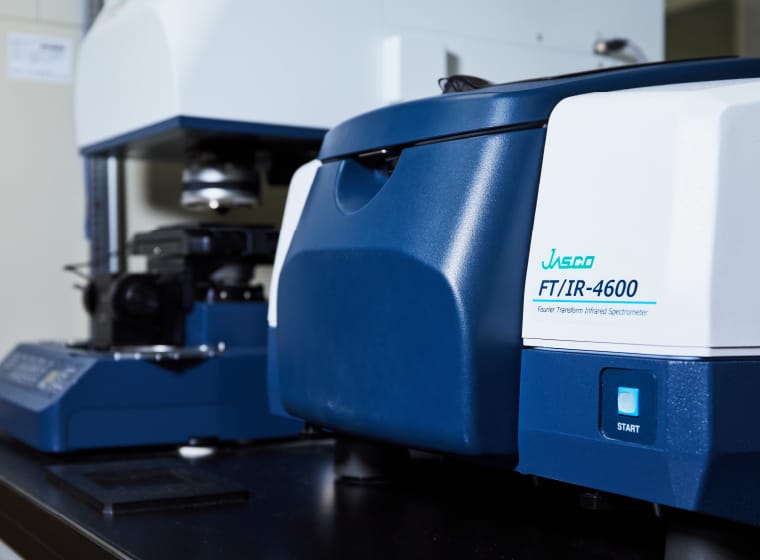

Fourier-transform infrared (FTIR) spectrometer

An FTIR spectrometer is a device that shines an infrared light beam on a sample, and then measures how much of the light passes through and how much is reflected off. As infrared light absorption varies depending on the molecular structure of the material, the device can be used to obtain information needed for substance identification. Based on this data, decisions can be made regarding sample composition (i.e., material analysis).

-

Differential scanning calorimeter (DSC)

A DSC is a device for measuring the heat flow of a sample by varying the temperature according to a specified program. By measuring the melting point, and then comparing this with the peak waveform, decisions can be made regarding the grade of sealant that should be used. Measuring the melting point makes it possible to obtain data that can be used for material identification.

-

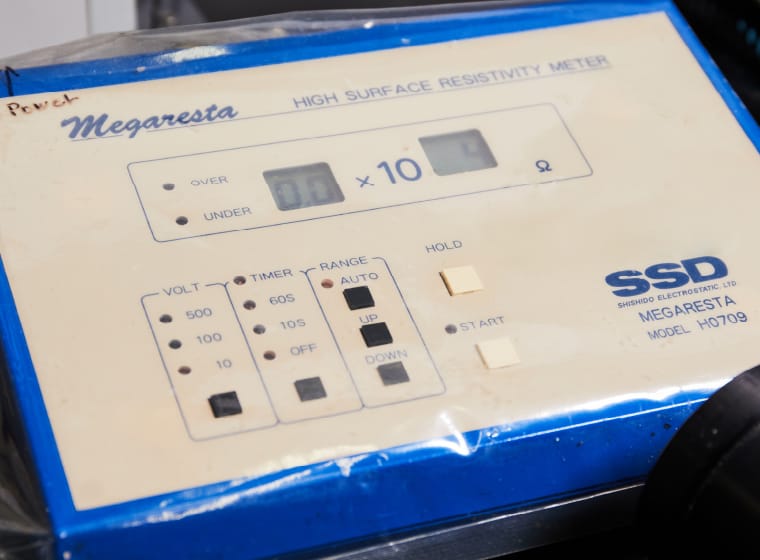

Surface resistance meter (Megarestor)

A surface resistance meter is a device for measuring the resistance when a current flows from one electrode to another. The resistance of the film surface can be used to evaluate the film’s antistatic properties and antifogging properties.

-

Thickness gauge (Micro-gauge)

A thickness gauge is a device that can be used to measure film thickness.

-

Environmental chamber

An environmental chamber is a device used to create an environment with specified temperature and humidity. The sample, packed with calcium chloride, is placed inside the chamber (set to a temperature of 40°C and relative humidity of 90%), and its water-vapor permeability can then be calculated from the weight and surface area.

-

Oxygen permeation testing device (MOCON)

This machine is used to test the permeation of oxygen through film. Film is placed inside the machine (set to a temperature of 23°C and relative humidity of 65%), and by detecting the oxygen molecules that permeate through the film, the degree of oxygen permeability can be measured.

-

Wet tensile strength test mixture (dyne liquid)

This liquid is used to test wet tensile strength (surface tension). The reagent is dripped onto the film, and the wet tensile strength of the film (which affects suitability for printing) can then be studied by examining whether the reagent is repelled or not.

-

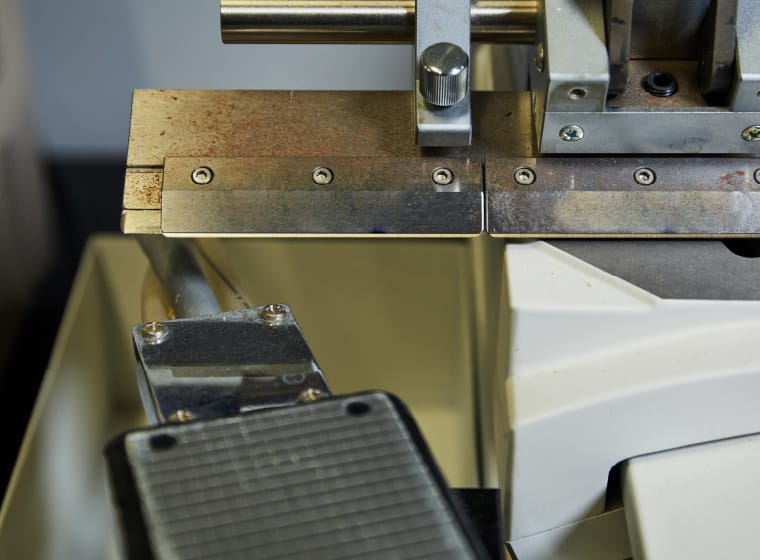

Microtome

A microtome is a machine used to cut frozen samples. Because the film or other sample that is placed in the machine is frozen, it can be cut cleanly without any extension. Microtomes are used to make samples, including cross-sectional observation.

-

Microscope

A microscope is a device used to obtain an enlarged view of a sample placed in it for observation. Utilizing samples prepared using the microtome referred to above, cross-sectional observation can be performed to measure such as the number of layers of which film is composed and its structural width. Having an enlarged view of the sample makes it possible to detect such as flaws that could not be seen with the naked eye. Implementing polarized light microscopy enables unevenness on the surface of the film to be detected.

-

Universal testing machine

A universal testing machine is a machine that applies tension, compression or loads to a sample and observes the changes in the sample. By applying tension, compression or loads, at a specified velocity, to a sample placed in the machine, values can be measured for the following physical properties: tensile strength, elongation, seal strength, laminate strength, and coefficient of static friction and coefficient of dynamic friction.

*By replacing the jig, it is also possible to test the piercing resistance, puncture resistance, seal opening strength as well as coefficient of static friction and coefficient of dynamic friction. -

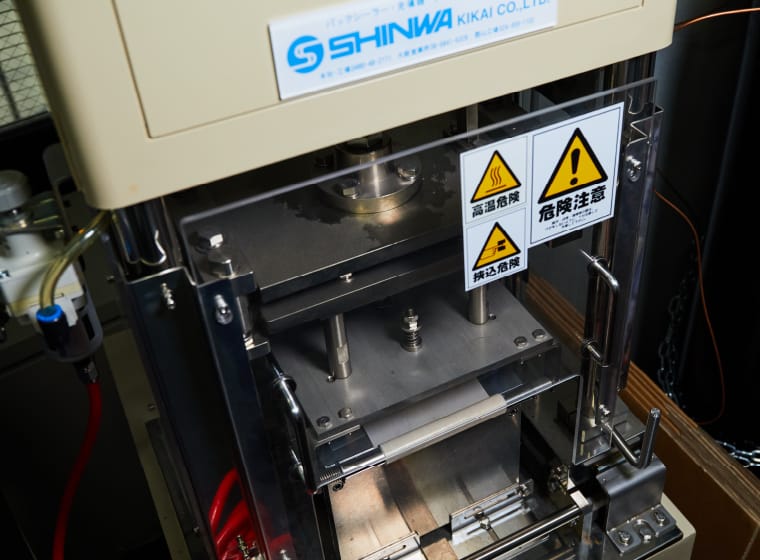

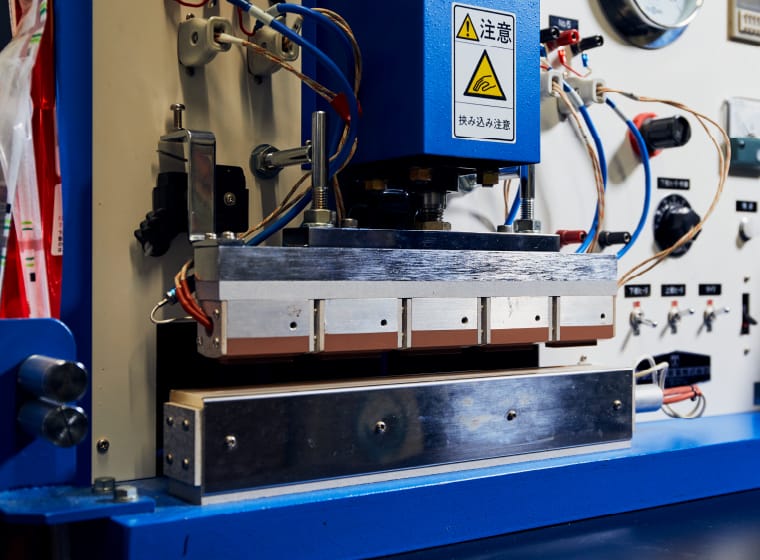

Semi-automatic sealing machine

This machine is used to seal the lid of containers. Once the sealing pressure, sealing time and sealing temperature have been set, it seals the lid to make the sample.

-

Digital force gauge

A digital force gauge is a machine that applies tension, compression or loads to a container’s lid to test the seal opening strength. By applying extension, compression or loads at a specified velocity to the lid that has been set in the machine, the force used when opening the seal (the seal opening strength) can be measured.

-

Seal tester

This machine introduces air into the sample to create internal pressure. The machine continues to increase the internal pressure inside the sample, and then measures the intensity of the pressure at the point when the sample bursts (i.e., the bursting strength). If the sample is kept at a specified constant internal pressure, air leakage (seal strength) can be investigated.

-

Constant-temperature drying oven

With this machine, the temperature is set to create a specified environment. The sample is hung up inside the machine (set to a temperature of 120°C), and the thermal shrinkage rate is calculated based on the extent to which the film shrinks.

-

Friction color fastness tester (Gakushin type rubbing tester)

This machine causes samples placed in the machine to move back and forth horizontally. When a load is applied, the samples rub against one another, and the frictional resistance of the samples—in terms of whether printing peels off, or whether holes or defects appear—can be assessed.

-

Heat seal tester

This machine is used to seal film together. By setting the sealing pressure, sealing time, and sealing temperature, film can be sealed to make a sample.

-

Jig used to measure heat seal strength

A load is applied to the sample, and after sealing the sample passes through the jig, and the length of peeling at the seal is measured to assess the heat seal strength.